Quality, Safety & Compliance

Pecca Leather

Quality

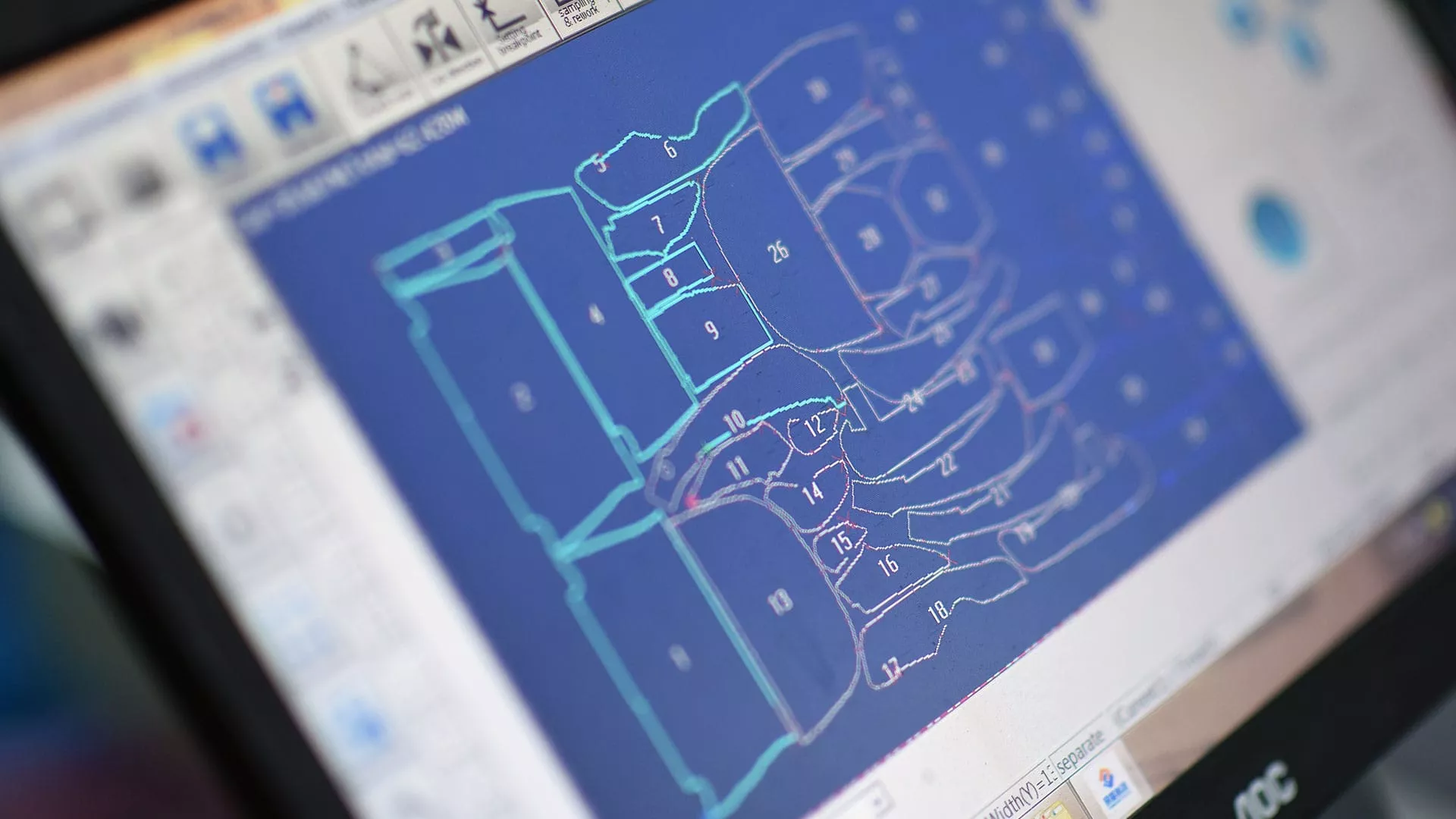

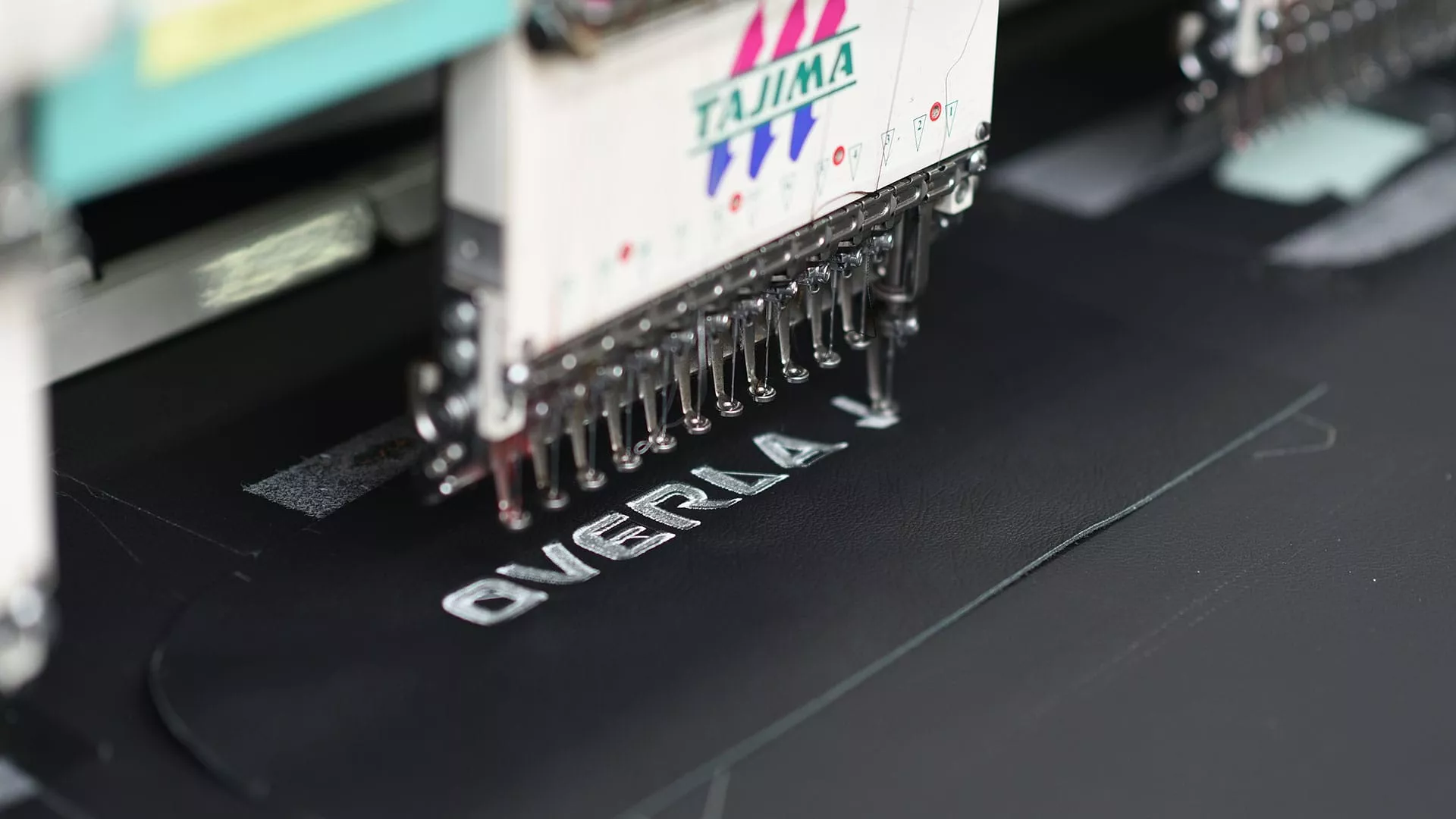

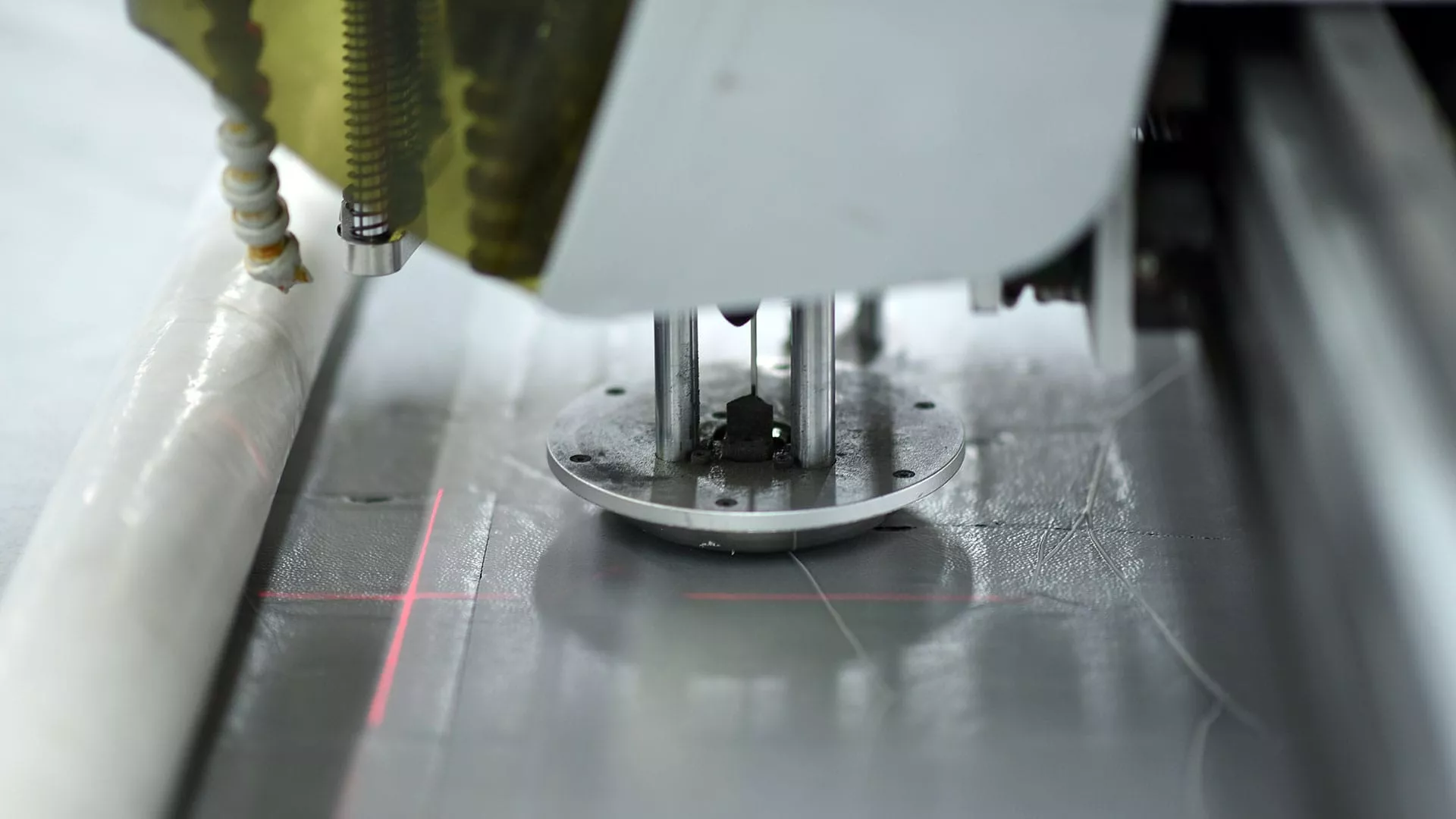

We have made substantial investments in cutting-edge machinery sourced from the United States of America, Germany, and Italy, including sewing, cutting, embossing, and perforation machines. Years of refinement and industry insights have led us to pinpoint dependable brands and models that consistently yield high-quality output.

This commitment to technology and equipment aligns with our dedication to quality, driving continuous improvement as we grow.

This commitment to technology and equipment aligns with our dedication to quality, driving continuous improvement as we grow.

Our commitment to stringent quality control is evident through meticulous checks at every stage – from leather selection to final delivery. Client feedback is paramount, ensuring utmost customer satisfaction.

Quality material forms the foundation of exceptional products. We exclusively employ top-tier automotive grade leather that adheres to stringent international standards. Sourced from reputable European and South American tanneries known for their environmentally-friendly practices, our leather undergoes both external specifications and internal laboratory tests upon arrival at our facility.

Quality material forms the foundation of exceptional products. We exclusively employ top-tier automotive grade leather that adheres to stringent international standards. Sourced from reputable European and South American tanneries known for their environmentally-friendly practices, our leather undergoes both external specifications and internal laboratory tests upon arrival at our facility.

Test

Procedures

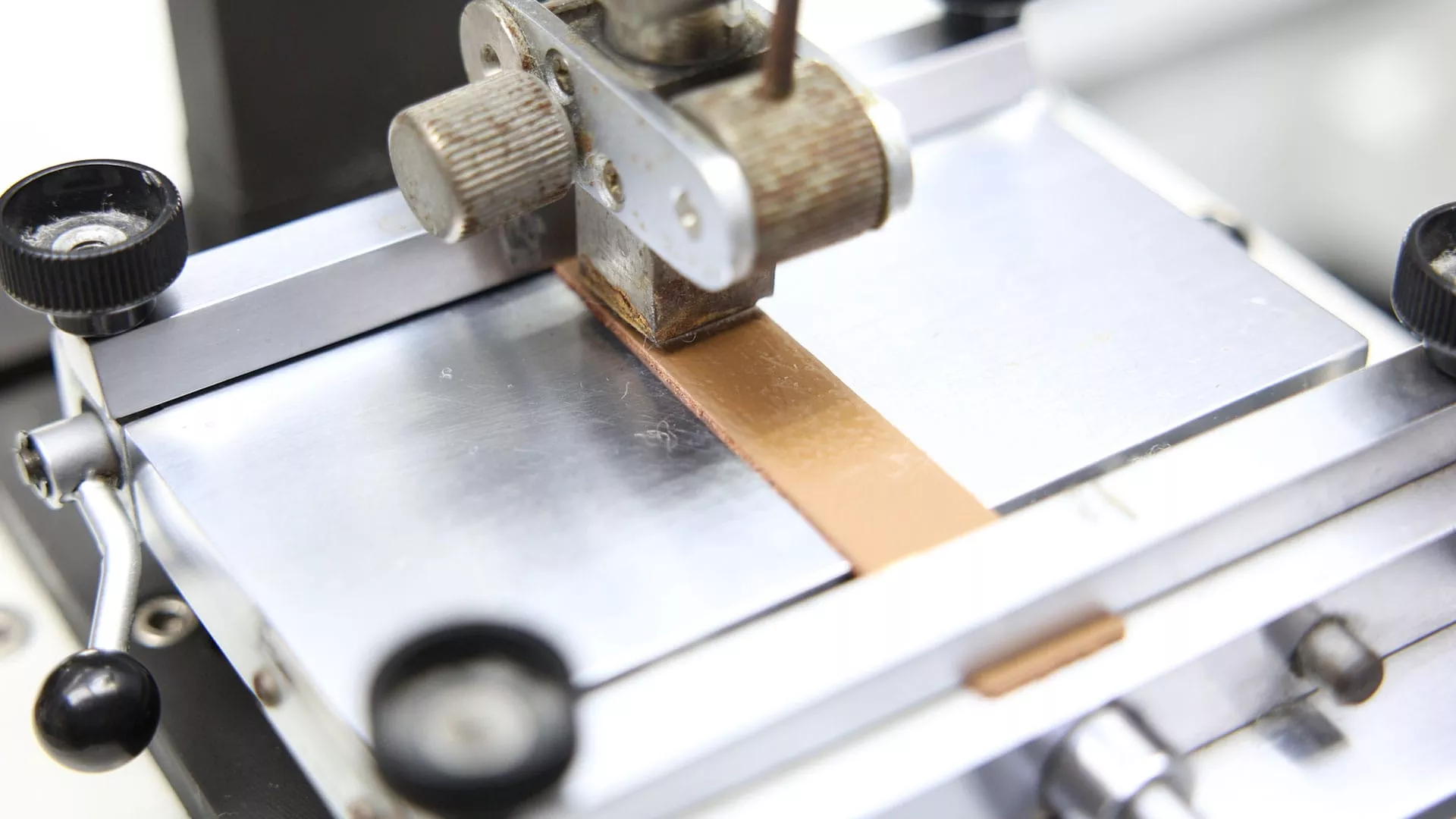

Throughout production, from material selection to checking, manufacturing, packing, and pre-delivery, rigorous inspections are performed. Pecca Leather has devised comprehensive test procedures and systems to ensure the quality of our final product. Production test procedures encompass the following:

Flexing Endurance

To ensure the absence of surface cracks after flexing within the designated cycles.

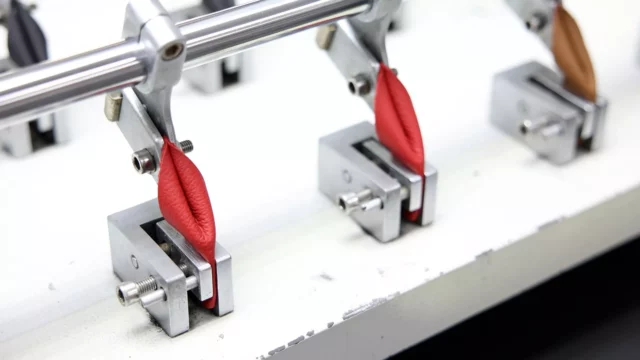

Tensile Strength

To assess leather strength, we measure the maximum load and elongation upon rupture.

Lultcs Rub Fastness

To evaluate colour transfer on the leather surface following rubbing within defined cycles.

Abrasion

To assess the degree of wear and tear on the leather surface following abrasion over specified cycles.

Colour Assessment

To verify the conformity of the incoming leather/leatherette against the master by using visual inspection and a colour reader to meet the specified standards.

Safety and

Compliance

Our car upholstery adheres to professional standards and stringent safety measures.

Our car seat covers are certified by Autoliv and MGA Research Corporation, passing airbag deployment tests. Utilising computerised airbag sewing machines is not only for your safety; it is mandated by our OEM clients.

Under MGA Research Corporation, we have extensively tested our car seat covers to meet or surpass Federal Motor Vehicle Safety Standards (FMVSS). This covers Side Impact Airbag Deployment and Suppression tests, ensuring proper functioning of front passenger seat sensors as per FMVSS 208.

Our car seat covers are certified by Autoliv and MGA Research Corporation, passing airbag deployment tests. Utilising computerised airbag sewing machines is not only for your safety; it is mandated by our OEM clients.

Under MGA Research Corporation, we have extensively tested our car seat covers to meet or surpass Federal Motor Vehicle Safety Standards (FMVSS). This covers Side Impact Airbag Deployment and Suppression tests, ensuring proper functioning of front passenger seat sensors as per FMVSS 208.