The automotive industry in Malaysia is undergoing a significant transformation, driven by the rising global demand for electric vehicles (EVs). As governments, businesses, and consumers prioritise sustainability and cleaner energy sources, Malaysia finds itself at a pivotal juncture in the transition towards an electrified future.

For automotive component manufacturers, this transition offers an array of emerging opportunities, particularly in supplying parts and systems essential to EV production.

In this article, we explore Malaysia’s EV market growth and highlight the diverse opportunities available for automotive component manufacturers to participate in this rapidly expanding sector.

Malaysia Market Growth and Projections

1. Significant EV Adoption

Malaysia’s automotive market has long played an important role in the nation’s economy, but the surge in EV adoption is reshaping its trajectory. Government policies such as tax incentives, import duty exemptions, and the development of charging infrastructure have accelerated consumer interest in EVs.

Collaborations with foreign EV brands are introducing a wider range of electric models to the local market, enhancing accessibility for Malaysian consumers.

2. Market Value Growth

The EV transition is poised to reshape Malaysia’s entire automotive industry landscape. Industry experts project strong growth in the EV sector in Malaysia over the next decade. This growth is fuelled by rising consumer demand, supportive policies, and increasing foreign direct investment in EV production facilities.

Furthermore, adjacent sectors such as the tyre industry are also evolving in response to EV adoption, given the different wear patterns and performance requirements of EVs compared to internal combustion engine (ICE) vehicles. This shift presents additional downstream opportunities for automotive parts manufacturing companies prepared to adapt to these new specifications.

Opportunities for Automotive Component Manufacturers

The growing EV market opens new avenues for automotive component manufacturers to diversify and expand their capabilities. While the core vehicle structure may remain familiar, EVs require specialised components that differ from traditional ICE vehicles.

The following are key areas where automotive parts manufacturing companies can capitalise on emerging demands:

1. Battery and Thermal Management Systems

EVs rely heavily on advanced battery technology, creating opportunities for manufacturers involved in battery enclosures, thermal insulation materials, and cooling system components.

As battery performance and safety are critical concerns, high-quality parts that contribute to optimal battery operation are in increasing demand. Thermal management components that regulate battery temperature ensure efficiency, longevity, and safety of the vehicle.

2. Lightweight Materials and Structural Components

To maximise efficiency and range, EV manufacturers prioritise lightweight materials such as aluminium alloys, composites, and high-strength plastics. Companies experienced in producing structural components, body panels, and interior parts using these materials can find new partnerships with EV brands seeking weight reduction without compromising safety or durability.

Opportunities also exist in the development of innovative bonding and joining technologies to assemble these materials effectively.

3. Electronic and Electrical Components

Unlike ICE vehicles, EVs depend extensively on sophisticated electronic systems, including power electronics, sensors, control units, and advanced wiring harnesses. Automotive component manufacturers with expertise in precision electronics manufacturing can play a vital role in meeting these specialised needs.

In addition, the demand for advanced driver-assistance systems (ADAS) and vehicle-to-everything (V2X) communication technologies opens further prospects for manufacturers supplying electronic modules and sensors.

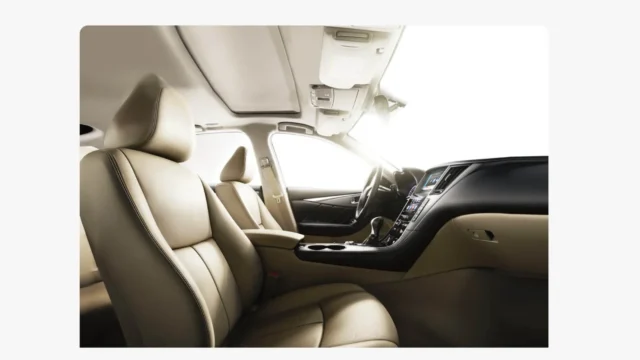

4. Premium Automotive Leather Upholstery and Interior Solutions

As the EV market evolves, consumer preferences increasingly lean towards premium, technologically advanced, and highly customised interiors. Automotive component manufacturers specialising in premium leather upholstery, trim, and high-end interior solutions have a unique opportunity to serve EV brands focused on luxury and comfort.

Innovations in sustainable and eco-friendly materials are particularly attractive, as EV consumers often prioritise environmental responsibility. High-quality seat covers, ergonomic designs, noise-dampening materials, and luxurious textures can enhance the appeal of electric vehicles, positioning manufacturers who excel in interior craftsmanship for long-term partnerships.

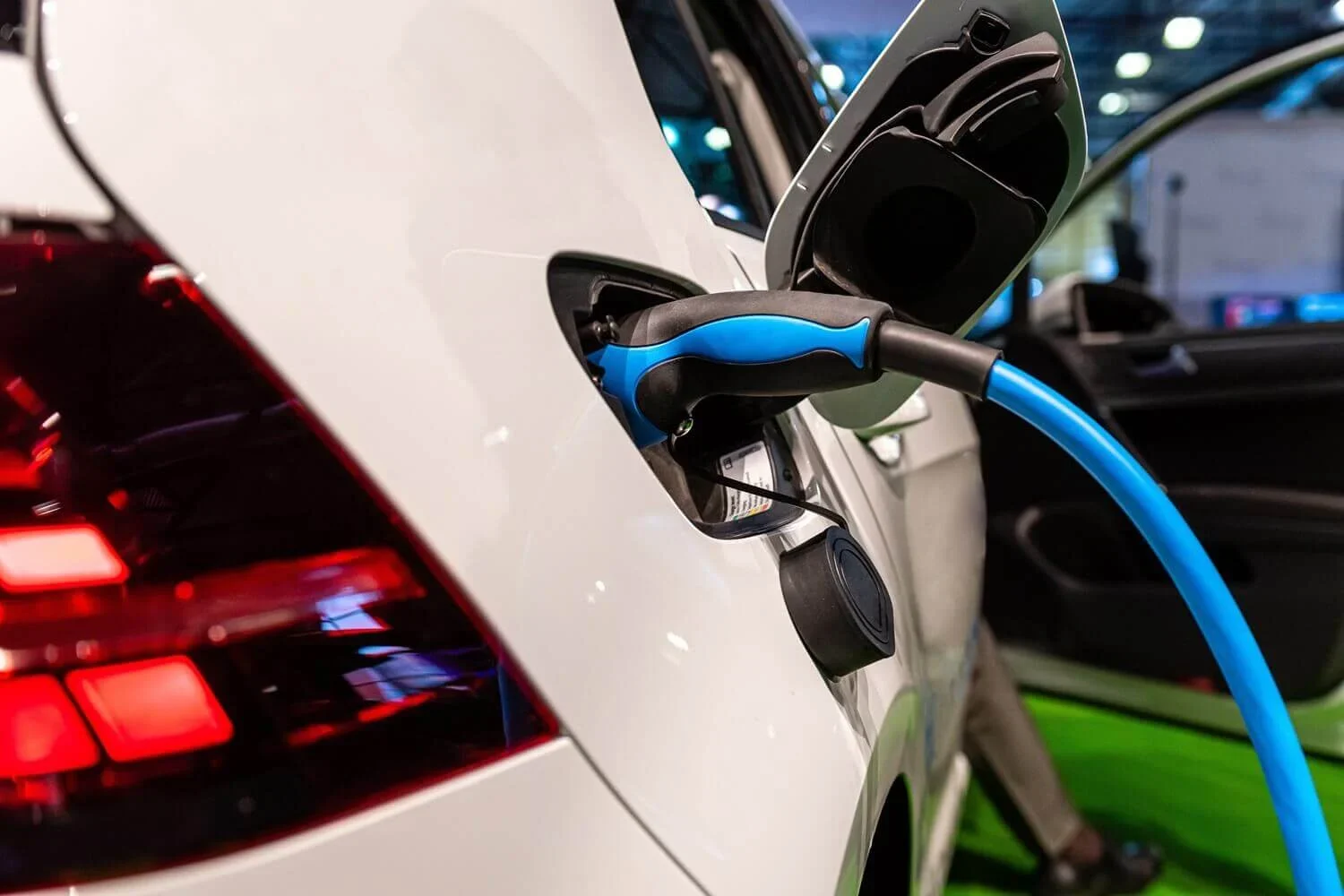

5. Charging Infrastructure Components

With the rapid expansion of EV charging networks across Malaysia, there is rising demand for components used in charging stations, such as connectors, cables, enclosures, safety modules, and cooling systems for fast-charging equipment.

Automotive parts manufacturing companies that diversify into these areas may secure a competitive advantage as the supporting infrastructure continues to grow. Collaborations with energy providers and charging network developers can also create new business channels.

6. Tyres, Suspension, and Braking Systems

EVs exert different loads and torque on tyres, suspension, and braking systems due to their instant torque delivery and heavier battery packs. This creates a need for specially designed tyres with lower rolling resistance, adaptive suspension components, and regenerative braking-compatible systems that can handle unique EV performance characteristics.

Manufacturers focusing on advanced rubber compounds, precision suspension technologies, and integrated braking solutions can align their R&D efforts with evolving market requirements.

7. Thermal Comfort and Climate Control Systems

Efficient climate control systems are crucial in EVs since traditional engine heat is not available to warm the cabin. This opens opportunities for manufacturers to develop innovative HVAC (heating, ventilation, and air conditioning) systems that are energy-efficient, compact, and capable of maintaining passenger comfort without compromising battery range.

Solutions such as heat pumps, advanced air filtration systems, and zonal climate control modules can become critical selling points for EV brands.

8. Noise, Vibration, and Harshness (NVH) Solutions

With quieter electric drivetrains, interior noise from tyres, wind, and road surfaces becomes more noticeable. Automotive component manufacturers have opportunities to provide advanced NVH solutions, including sound insulation materials, vibration dampers, and precision-fitted interior components that enhance cabin quietness and ride comfort.

Closing

As Malaysia continues its journey towards becoming a regional hub for electric vehicles, the ecosystem supporting EV production will rely heavily on the capabilities and adaptability of local automotive component manufacturers.

Companies with established expertise in automotive components — such as Pecca Group, which focuses on seat covers and interior trim manufacturing — represent part of the local ecosystem that may contribute to supporting both current and future EV production needs as the industry evolves.